Balancing Future Readiness and Immediate Need for Pasco’s Wastewater Treatment Plant

Pasco, Washington, began as a small railroad town and gradually evolved into an agricultural hub. Unlike neighboring cities, Pasco’s population growth stayed modest until the early 2000s when residents relocating within the Tri-Cities area accelerated new housing developments, apartments, and industry.

The City of Pasco (City) set out to upgrade its wastewater treatment plant (WWTP) to meet escalating demand caused by its population more than doubling in the past 20 years. Since its inception in the 1950s, the City’s WWTP has undergone various upgrades and improvements in response to evolving Federal Water Pollution Control Act (Clean Water Act) updates, state water quality standards, and treatment technology advancements. The City’s most recent project is the start of a series of upgrades over the next two decades that will support its efforts to modernize infrastructure for public health, environmental stewardship, and water quality preservation.

For the inaugural phases of this WWTP improvement project, the team had to balance three distinct challenges:

- Designing and receiving approval for the project in just 10 months to receive a State Revolving Fund (SRF) loan.

- Crafting design solutions that meet the City’s current critical capacity needs and projected continued urban growth.

- Maintaining design and construction schedules amidst a pandemic and subsequent related supply chain disruptions.

Overall Facility Improvements That Meet Cost and Quality

Sustained rapid growth and extensive infrastructure needs across all areas of public works created financial pressures that made minimizing this project’s fiscal impact important. To balance the often at-odds objectives of cost-consciousness and high quality, the project team prioritized creatively reusing existing infrastructure.

After careful planning to strike the right balance, the project team moved forward with a final design that nearly doubled the capacity of the facility through:

- Two new aeration basins and modifications to existing aeration basins.

- An expanded blower building with added and modified blowers.

- Enhancements to the return activated sludge (RAS) pump system.

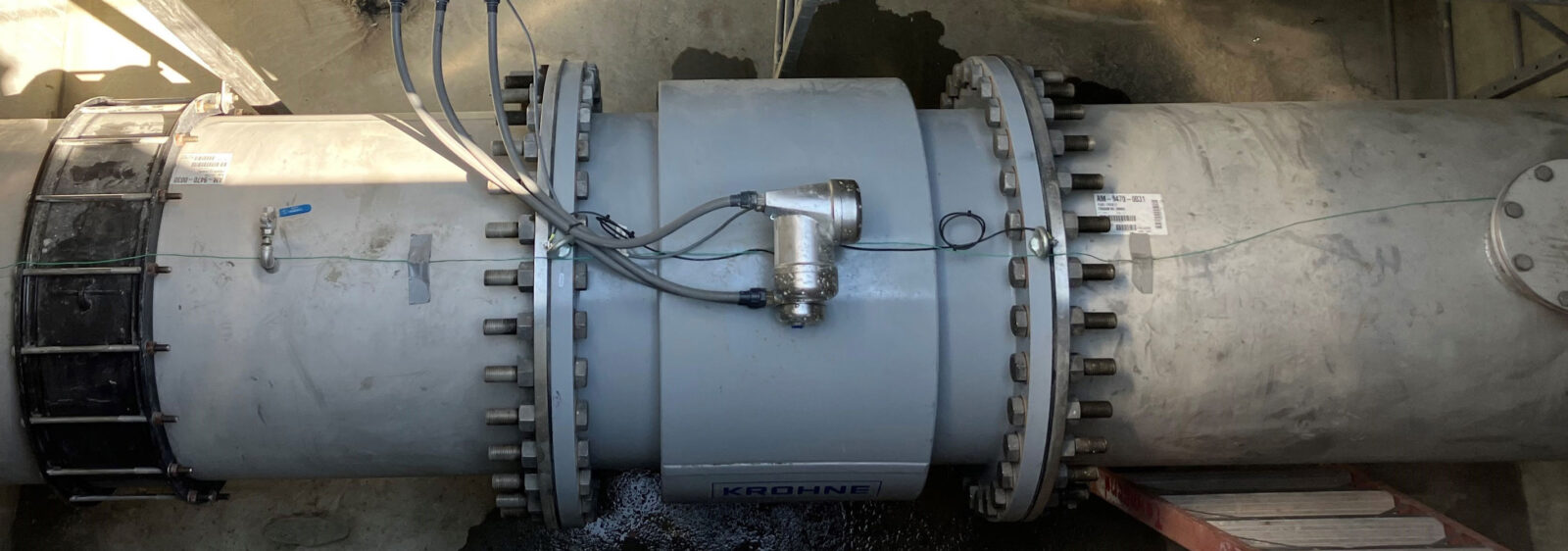

- A new effluent flowmeter facility.

- 1,150 feet of new 42-inch diameter outfall piping.

- New primary power switchgear and related electrical, control systems, site work, and yard piping.

Solutions That Foreground Sustainability

Wastewater treatment plants inherently play a crucial role in environmental protection, specifically in maintaining the quality of water bodies. The treated effluent from the City’s WWTP is responsibly returned to the Columbia River. This river, renowned as the largest by volume flowing from the Americas into the Pacific Ocean, is integral to the ecological health and vibrancy of the region.

The project team designed the facility for longevity and to minimize the depletion of natural and physical resources and energy consumption. The approach included:

- Modification of the existing aeration basins to meet modern treatment standards, which minimized new material use.

- A new effluent outfall diffuser system installed 1,200 feet into the Columbia River at a deeper location, which increases capacity and effectiveness while protecting aquatic biota. For more on the rare, complex installation process, see this post.

- Decommissioning of the intermediate clarifier, which will be repurposed as a filtration equalization storage tank in future project phases.

- A seasonally flexible anoxic/anaerobic selector to reduce the blowers’ overall energy consumption in the warmer months when nitrification occurs and the winter months when nitrification is absent.

- New energy-efficient high-speed turbo blowers and mixers, fine pore diffusers, and individual zone dissolved oxygen controls that meaningfully reduce the overall energy demand of the system.

A Balance Between Future-readiness and Immediate Need

The last major expansion of the WWTP happened in the late 1990s. Initially, this expansion could accommodate the area’s growth, but due to the sustained rapid increase in population and industrial development, which didn’t follow the area’s historical boom and bust cycles, the plant’s capacity was soon outstripped.

Consor collaborated with the City on the WWTP Facility Planning effort in 2016, which quickly identified significant issues with capacity, redundancy, and the age/condition of the facility. With continued rapid growth and a treatment plant reaching its limits, the City and Consor needed to find immediate solutions to gain “breathing room.” Together, they identified several options that, while not preferred as long-term solutions, were able to rapidly increase plant capacity by 15 to 20%. These short-term improvements included chemically enhanced primary treatment (CEPT), recuperative thickening, trickling filter forced ventilation, and aeration basin bioaugmentation.

With the immediate needs addressed, the project team could prioritize future readiness for capacity and water quality standards in this next project phase. Improvements included:

- An aeration basin option capable of meeting both current and anticipated discharge requirements for the next 10 to 20 years such as ammonia removal from the wastewater stream, which is not currently required but can be harmful to the environment.

- Outfall piping constructed mostly of high-density polyethylene (HDPE) with a service life expectancy up to 100 years and sized larger than the required 20-year flow projections.

- Pre-installation of expansion water stops, rebar anchors, and strategically placed utilities that are ready for future expansion with minimal demolition.

Proactive Construction Management and Delivery

Faced with the dual challenges of limited capacity and ongoing growth, the timely completion of this project and the seamless commencement of a subsequent project were of utmost importance. The fact that the WWTP had to remain in operation to provide necessary services to the community also made construction more complicated. The onset of COVID-related supply chain disruptions threatened to extend the duration of this project and impact the start of the next critically needed phase of work. The project team diligently addressed these unanticipated delays and avoided delaying the subsequent project by:

- Operating the WWTP during construction by building the new aeration basins, then shifting operation to the new basins while the old ones were being reconfigured (see images below).

- Holding bi-weekly meetings to discuss time-sensitive or critical construction items.

- Coordinating directly with suppliers to mitigate supply chain disruptions caused by the pandemic.

- Having a full-time resident project representative (RPR) on site to coordinate daily plant operations with construction activities, which addressed unforeseen conditions typical at brownfield sites.

Despite the myriad challenges this complex project presented, the collaborative effort in planning, design, funding, and construction set up the Pasco community with a WWTP equipped to handle its growth and evolution. Evidence of this project’s complexity and the team’s successful approach, it recently won APWA Washington’s Project of the Year Award in the Environment $5M – $25M category, and it was recognized as a 2024 Top Project by Wastewater Digest! Read the article or watch the interview.