A Small Utility’s Blueprint for Scalable Biosolids Drying

For small utilities, biosolids management can be a balancing act. Storage fills up during wet seasons when land application, or the use of treated sewage sludge to condition or fertilize soil, isn’t possible. Scheduling depends on external haulers or the availability of local farmers. Advanced solids processes that address these challenges typically have high costs and require complex project delivery approaches that don’t scale down directly with capacity.

The City of Scappoose, Oregon, faced such challenges for years—its biosolids program contended with odor, storage limitations, and land application issues. In response, the team developed a practical solution that would mitigate the program’s deficiencies by addressing the hurdles of scaling a biosolids drying process to a modest budget.

The result was a system that improved efficiency, bolstered community relations, and offered a model for other utilities. The project also included Oregon’s first air quality screening for a biosolids dryer, setting a regulatory pathway for similar systems.

The Problem: Storage, Odor, and Operational Limits

Scappoose’s wastewater treatment plant used a screw press to produce Class B biosolids as dewatered cake. The biosolids were then stored in a covered pole barn (figure 1) and land applied seasonally. During the wet season, the barn’s capacity was nearly exhausted. Managing the stored solids required rapid inventory reduction during each land application season, which was dependent on availability of local agricultural fields.

The labor-intensive process strained limited resources, and the potential for odor impacts on the community weighed on the minds of the staff. Any solution would need to reduce the operational burden, as well as make the most use of existing infrastructure to minimize capital costs, preserve past investments, and expedite construction.

Approach: A Scalable, Resource-Conscious Solution

The design built upon proven elements already in place: a screw press producing cake at 18% to 20% total solids and a pole barn that could serve a role in the upgraded process.

The project team evaluated drying technologies that would process large batches a few times per week. This rate would match the City’s staffing capacity, avoiding the need for continuous oversight and inventory management. The optimized system would also need to fit within a constrained footprint and integrate with existing equipment, as well as stay within a $2 million construction budget.

Design Solution

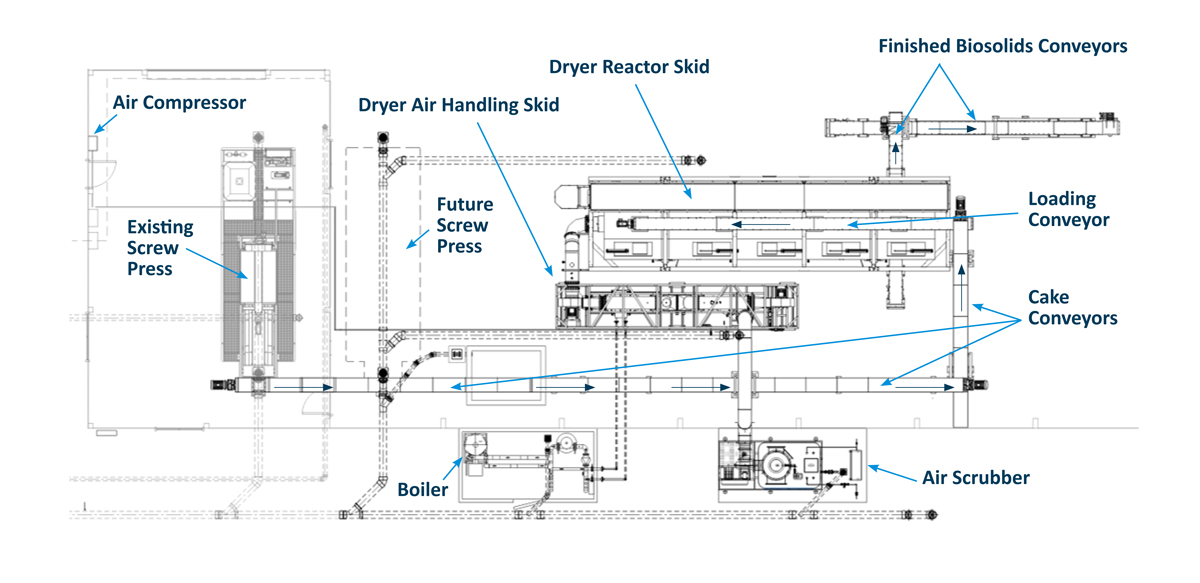

The final design (figure 2) used a low-temperature dryer that processes batches of approximately 16,000 pounds of dewatered cake two to three times per week, producing Class A biosolids at over 90% total solids. Large batch operation only requires operators to be present during loading and unloading, with SCADA monitoring during processing. Beyond reducing the biosolids volume and odor, the dryer’s low operating temperature is safer for operators and eliminates the need for a fire suppression system.

Regulatory Coordination

Scappoose’s biosolids dryer was the first in Oregon to undergo formal air quality screening to determine if permitting was necessary for the facility’s emissions. Working closely with the Oregon Department of Environmental Quality, the project team quantified emissions from the boiler, dryer, and backup generators using vendor-supplied data and EPA standards.

The analysis showed that projected emissions of PM-10, NOx, CO, VOCs, SO2, CH4, Pb, and NH3 were well below the permitting threshold of 10 tons per year of any single pollutant from all sources at the site. The system was classified as de minimis, allowing the project to proceed without further evaluation—exemplifying a regulatory pathway for reference by similar systems.

Construction and Adaptation

Working with owner-supplied equipment in an existing facility meant tolerances were tight, but the design still needed enough flexibility to adapt to actual conditions. The design team specified that contractor-supplied elements with exceedingly tight tolerances must be field-fitted to provide proper alignment. A process was also incorporated into the contract documents that required the contractor to field-verify the owner-supplied equipment layout against control points relied upon during design.

A dedicated bypass conveyor was eliminated from the project during design due to cost, which meant a more labor-intensive process in the event of a bypass. During construction, the team identified an opportunity to repurpose an existing conveyor for bypass operations. The City, contractor, Consor, and the equipment manufacturer pivoted to integrate the existing asset, enhancing the overall efficiency of the project while optimizing costs.

Results: Efficiency and Community Benefit

Since startup, the new drying system has delivered measurable improvements. Biosolids are now dried to over 90% total solids, reducing volume by more than 75% and making the material easier to store and transport. Solids that previously required a front loader for handling and occupied approximately 50 square feet can now be stored in a single super sack.

The volume reduction has alleviated seasonal inventory pressures and provided scheduling flexibility. Land-application partners have responded positively, with farmers opting to apply the material themselves rather than rely on City resources. These efficiency gains have freed up limited staffing for other operational needs.

With odors significantly reduced and storage needs met, the City has improved overall plant performance and strengthened public opinion in its biosolids program. The project’s success also earned it the League of Oregon Cities 2025 Award for Excellence, highlighting the City’s innovative and practical approach to turning waste into a reusable agricultural resource.

Lessons Learned

Scappoose’s experience offers practical takeaways for other small utilities facing similar constraints:

- Large batch drying can work for small systems. By designing the process around staffing schedules and capacity, utilities can reduce labor demands.

- Existing infrastructure value can be maximized. Incorporating existing equipment, like the screw press and storage barn, helps control costs and simplify integration.

- Flexibility matters during construction. Building adaptability into the design allows for critical field adjustments and leaves room for opportunities that emerge during construction.

As utilities face rising hauling costs, tighter land application restrictions, and increasing regulatory responsibilities, approaches like Scappoose’s biosolids dryer demonstrate that innovative solutions don’t always require new facilities or large budgets. It just takes a clear goal, a committed team, and a willingness to work through the details.